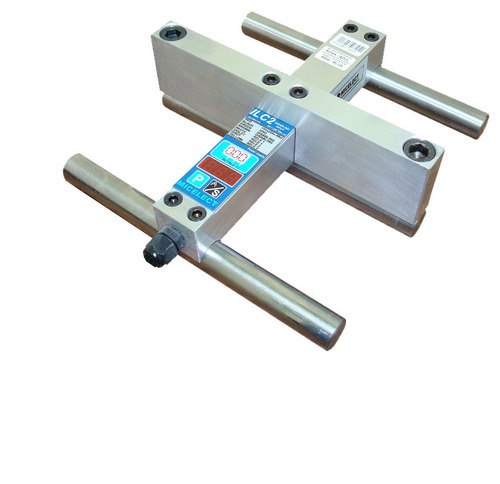

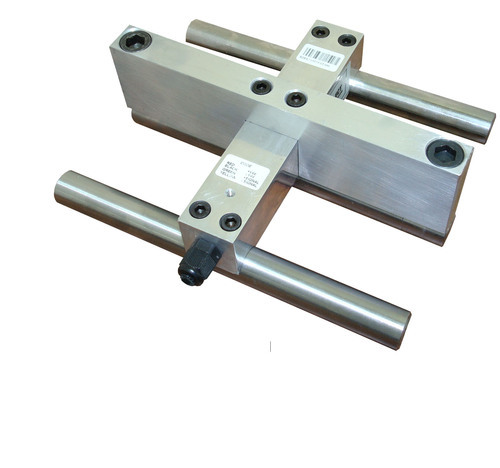

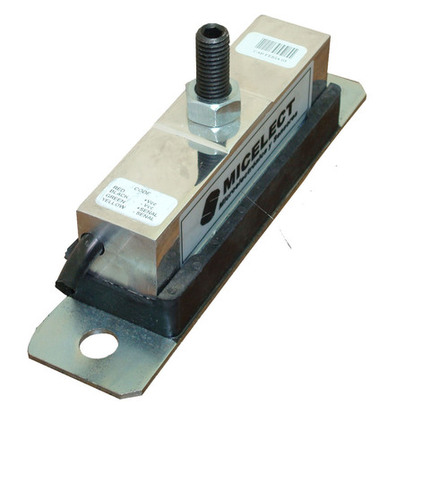

Hydraulic Sensor

Product Details:

- Type Pressure Sensor

- Noise Level <70 dB

- Load Capacity Suitable for industrial hydraulic systems

- Voltage 24V DC / 220V AC

- Usage Fluid Pressure Monitoring, Industrial Automation

- Material Stainless Steel / Aluminum

- Drive Type Hydraulic

- Click to View more

Hydraulic Sensor Price and Quantity

- 11500 INR/Piece

- 1 Piece

Hydraulic Sensor Specification

- <70 dB

- Instantaneous response

- Suitable for industrial hydraulic systems

- Up to 1000 Bar

- 24V DC / 220V AC

- Stainless Steel / Aluminum

- Fluid Pressure Monitoring, Industrial Automation

- -40C to +85C

- Built-in overload protection

- Hydraulic

- Electronic Pressure Sensing

- Pressure Sensor

- 220V/50Hz or customizable

- Electronic Circuit Board

Hydraulic Sensor Trade Information

- 5 Piece Per Day

- 1-7 Days

Product Description

A hydraulic sensor, otherwise called a tension sensor or hydraulic strain sensor, is a gadget intended to gauge the strain of a hydraulic liquid inside a hydraulic framework. Hydraulic frameworks are normally utilized in different modern and mechanical applications, like in large equipment, car stopping mechanisms, aviation, and then some. Observing and controlling hydraulic strain is essential for guaranteeing the appropriate activity and security of these frameworks.

FAQs ofHydraulic Sensor:

Q1: What is a hydraulic sensor?

A1: A hydraulic sensor is a gadget intended to gauge the tension of hydraulic liquids inside a hydraulic framework. It gives important data about the strain levels in the framework.

Q2: For what reason are hydraulic sensors significant?

A2: Hydraulic sensors are vital for keeping up with the protected and productive activity of hydraulic frameworks. They assist with forestalling overpressure, screen framework wellbeing, and give information to control and input inspirations.

Q3: What sorts of hydraulic sensors are accessible?

A3: There are different kinds of hydraulic sensors, including pressure sensors, pressure transducers, and strain switches. These sensors are utilized to quantify and screen the strain of hydraulic liquids.

Q4: How do hydraulic sensors work?

A4: Hydraulic sensors commonly work by utilizing a stomach or a strain measure to distinguish changes in hydraulic tension. At the point when strain is applied, these parts distort, and this misshapening is changed over into an electrical sign, which can be estimated and deciphered.

Q5: What are the normal utilizations of hydraulic sensors?

A5: Hydraulic sensors are utilized in a large number of utilizations, including hydraulic chambers, hydraulic siphons, hydraulic power units, and hydraulic control frameworks. They are fundamental in applications where exact tension control and checking are vital.

Reliable Pressure Sensing for Industrial Applications

Designed for durability and precision, this hydraulic sensor excels in challenging industrial settings. With robust IP67 protection and overload safeguards, it ensures reliable operation even in harsh environments. Its rapid response time and high accuracy enable effective monitoring and control of hydraulic systems, such as those found in presses and lifters. The threaded mounting design streamlines installation, while factory pre-calibration guarantees consistent performance from the outset.

Flexible Connectivity and Simple Integration

The sensors dual output options (analog 420 mA and digital) facilitate seamless integration with both modern and legacy industrial control systems. With a versatile 3-wire connection and compatibility with various voltage supplies (24V DC or 220V AC), it adapts easily to distinct monitoring and automation setups. Its compact form factor and reasonable weight make it suitable for space-constrained hydraulic assemblies.

FAQs of Hydraulic Sensor:

Q: How is this hydraulic sensor installed within hydraulic systems?

A: The sensor is installed using a threaded BSP or NPT mount, allowing secure and leak-resistant attachment to hydraulic lines or equipment. Its compact dimensions ensure straightforward integration, even in space-restricted setups.Q: What output signals are supported by the hydraulic sensor?

A: This sensor provides both analog (420 mA) and digital output signals, making it compatible with a wide variety of control and monitoring devices found in industrial automation.Q: When should this sensor be used for pressure monitoring?

A: It is ideal for real-time monitoring in environments requiring fast, precise, and reliable fluid pressure measurement, such as in hydraulic pumps, lifters, and presses operating at pressures up to 1000 Bar.Q: Where can this hydraulic sensor be effectively deployed?

A: This sensor is suitable for a broad range of industrial applications, particularly where robust protection (IP67), high pressure tolerance, and rapid response are essentialsuch as in factories, production lines, and heavy machinery settings.Q: What is the process for calibrating this sensor?

A: The sensor comes factory pre-calibrated, eliminating the need for onsite calibration before use. This ensures accuracy and simplifies the setup process for users.Q: How does the sensor safeguard hydraulic systems during operation?

A: The device incorporates built-in overload protection, which helps prevent damage from pressure spikes, contributing to the overall safety and reliability of the hydraulic system.Q: What are the key benefits of using this hydraulic sensor?

A: Users benefit from high accuracy, fast response, hassle-free installation, broad voltage compatibility, and reliable performance even in demanding industrial environments. Its rugged design and overload protection make it a dependable choice for critical pressure monitoring tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry